Room temp.

DHW

Operation

Installer

| Status: | HP + Add |

| Tank upper °C | 0 (60) |

| Tank lower °C | 0 (60) |

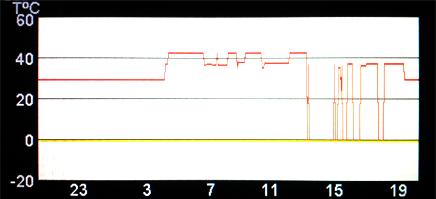

| Primary flow 1 °C | 0 (43) |

| Returnn flow °C | 0 |

| Radiator pump | On |

| Mixing valve | Open |

| Delay mixing valve | 0 |

| Electric power kW | 0.0 0.0 0.0 |

| Current L1/L2/L3 | 0 |

| Total operation time h: | 19 |

| Max primary flow °C | 0 |

| Consumption kWh | 19 |

| Compressor: | |

| Operation time /24 h:m | 00:00 |

| Compressor: | Off |

| Charge pump | Off 0% |

| Brine pump | Off |

| HP in/out °C | 0.0 / 0.0 |

| Heating circuit 1 | |

| Heating circuit 2 | |

| Heat pump | |

| Electric heater | |

| Upper tank | |

| Remote control | None |

| Communication | |

| >> | |

| Latest alarm: | Time | HP(b) | LP(b) | SH(K) | I(A) |

| Stored alarms: | |||||

| Type | Stops | Latest |

| Stop, high compr temp | 0 | - |

| Stop, low evaporation | 0 | - |

| Stop, high evaporation | 0 | - |

| Stop, low suct gas exp.valve | 0 | - |

| Stop, low evapor exp.valve | 0 | - |

| Stop, high evapor exp.valve | 0 | - |

| Stop, low superheat exp.valve | 0 | - |

| 13. Test current sensors | 0 |

| Scanning L1, L2, L3 | |